My Projects

01

Nitya: A floating waste collection boat

- Designed and developed a novel water surface cleaning mechanism, “Nitya,” featuring a conveyor system and waste accumulator for efficient waste collection.

- Conducted experimental tests to determine the sliding coefficient of friction (0.708) between the rollers and the conveyor belt, which was crucial for power calculations.

Engineered the system to operate efficiently with a power requirement of 2.28 Watts. - Optimized the waste accumulator mechanism by analyzing velocity, selecting a crank wheel diameter of 55 mm corresponding to a maximum flap velocity of 0.4 m/s.

- Designed a smartphone-based navigation system using a Bluetooth module and Arduino Uno for enhanced control.

- Utilized green materials for cost-effective and environmentally friendly construction, offering an efficient alternative to conventional water cleaning methods.

- Conducted a comprehensive risk assessment and fault tree analysis to ensure system reliability and safety

02

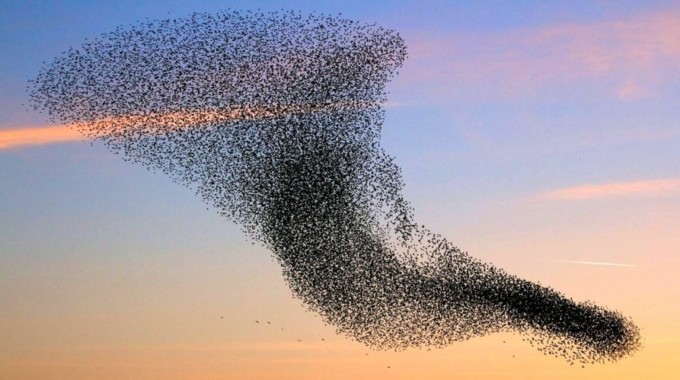

Swarm Robotics

Research Based on Collective Intelligence of Social Insects

- Identified the latest research contributions, methodologies, and key findings that have shaped the development of swarm robotics over the years.

- Conducted an extensive survey of peer-reviewed literature and relevant academic works, to gain a comprehensive understanding of the current state and prospects of swarm robotics.

03

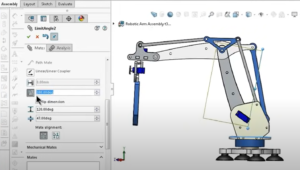

Design of Robotic Gripper

- Designing and Modelling of a robotic gripper using Fusion360; 3D printing and functional testing of CAD model for prototype.

04

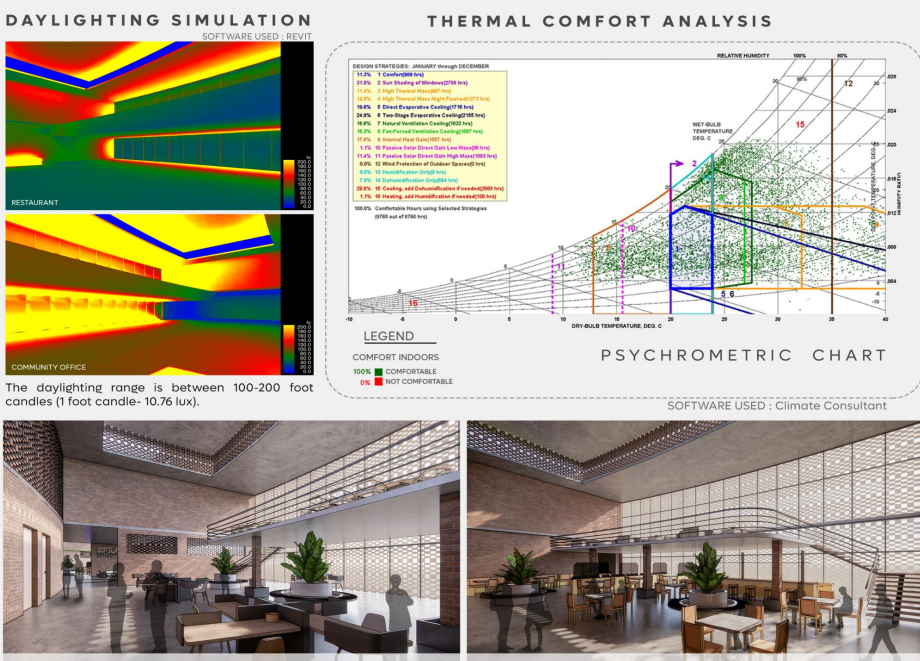

Team TEJASVI

U.S. Department of Energy Solar Decathlon 2023 Design Challenge

-

-

Designed a hybrid ventilation system for human comfort using Revit software and calculated the annual energy consumption for a stadium in Madhya Pradesh.

-

05

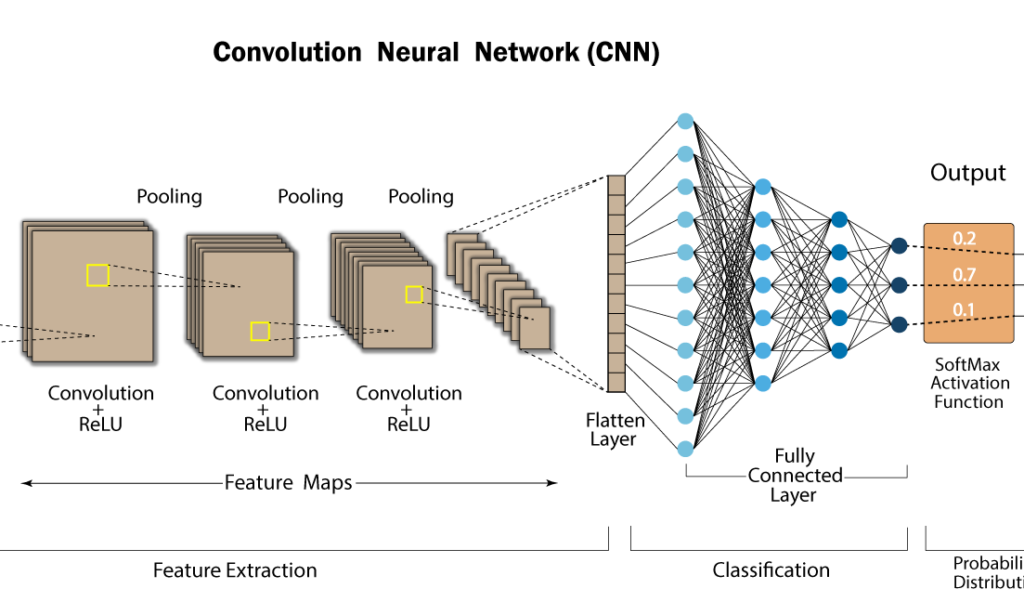

Neural Network Classifier for obstacle detection

- Developed and trained a Neural Network Classifier for obstacle detection in autonomous vehicles.

- Gathered and preprocessed a labeled image dataset, encompassing various obstacle types, weather conditions, and lighting situations.

- Designed a Convolutional Neural Network (CNN) architecture tailored to the obstacle detection task.

- Split the dataset into training, validation, and testing subsets for model assessment.

- Optimized hyperparameters and fine-tuned the model’s performance.

06

Generative Design using GANs

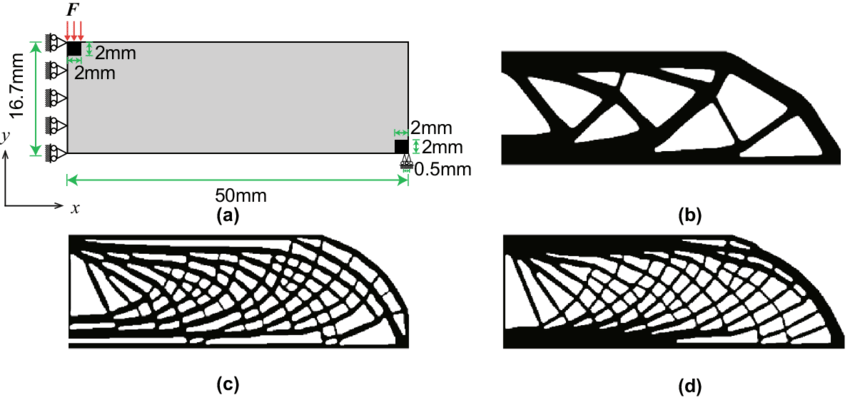

- Developed a generative design system for MBB (Minimum Bounding Box) beam structures.

- Leveraged Generative Adversarial Networks (GANs) for innovative design generation.

- Generated a topology-optimized image dataset using the SIMP (Solid Isotropic Material with Penalization) method in Python.

- Conducted image processing and hyperparameter tuning for GAN model training.

- Adeptly applied GAN-generated designs to the field of MBB beam engineering.

- Demonstrated the fusion of AI and engineering to streamline design processes.

07

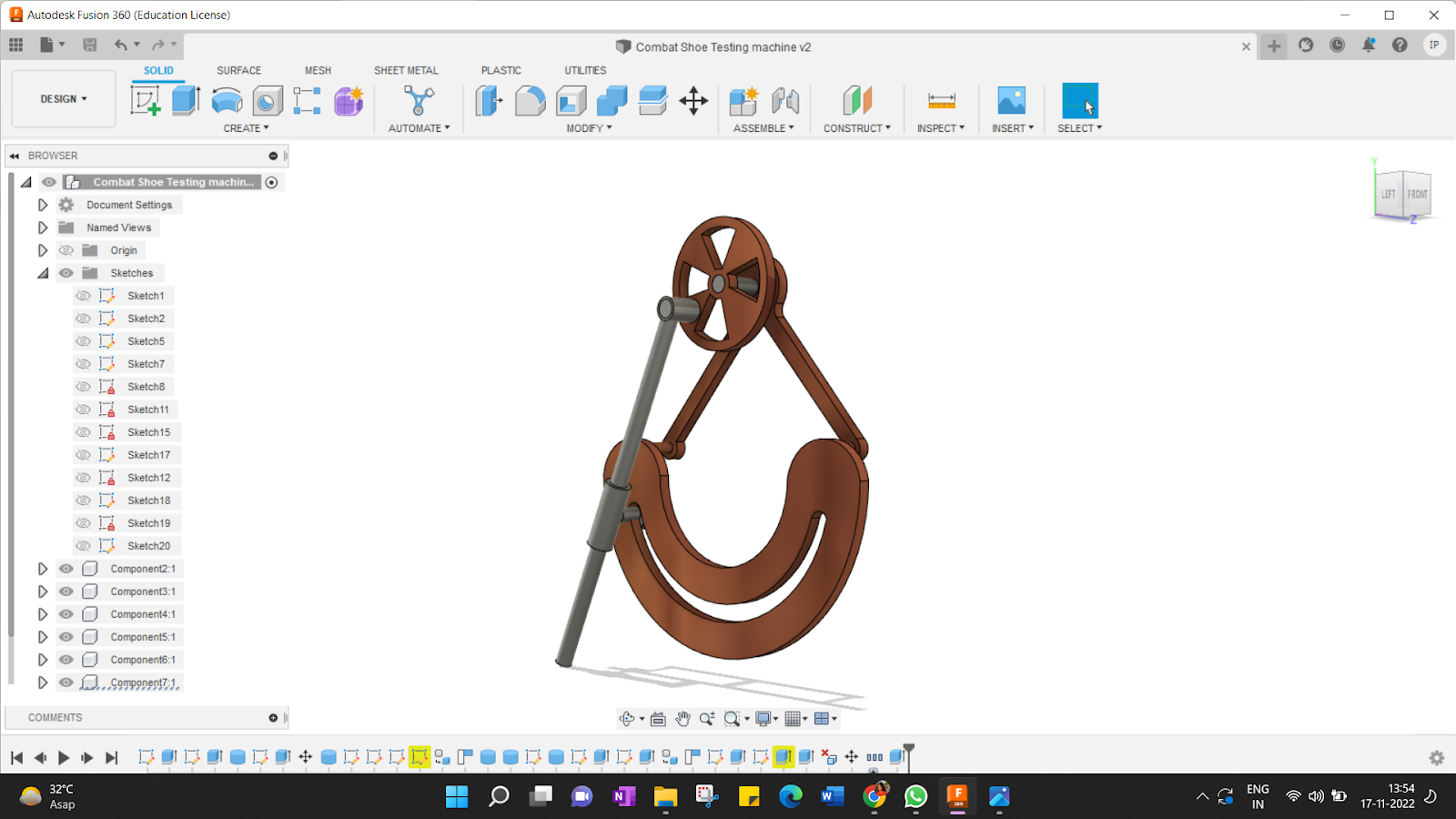

Design of an innovative testing machine for combat shoes

- Conceptualized and designed an innovative testing machine specifically tailored for evaluating the performance and durability of combat shoes under rigorous conditions.

- Implemented real-time data collection from load cells and pressure sensors using Arduino and USB connectivity.

- Created a graphical user interface (GUI) using Python’s Tkinter library for data visualization.

- Designed the interface to display real-time load, pressure, and temperature data for precise control.

08

Machine Predictive Maintenance Classification

- Gathered data from industrial sensors within a manufacturing company to predict maintenance needs, ultimately preventing equipment breakdowns and cost savings.

- Conducted thorough Exploratory Data Analysis (EDA) to gain insights into the dataset by finding the most relevant features using Matplotlib in Python.

- Implemented robust Data Preprocessing to prepare the dataset for modelling, including handling missing values, feature scaling, and encoding categorical variables using Pandas.

- Evaluated 5 ML models and selected Gradient Boosting Classifier based on the model accuracy.

09

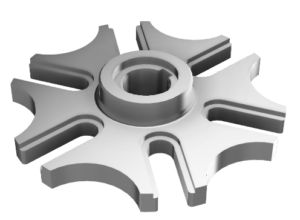

Gear Box Design

- Developed a gearbox to deliver 42 kW power with a power efficiency of 95%. The steady sate input speed was 1500 rpm and the steady state output speed was 268 rpm. The gears involved were helical and the gear-train was a two-stage reverted one.

- Developed a detailed design calculation report, and a general assembly drawing on Catia. It also included a detailed drawing for intermediate shaft.

10

Predictive Analysis of carbon steel using Regression Model

- Developed a linear regression model to predict the crack growth rate in a standard compact tension specimen of carbon steel when subjected to cyclic loading.

- Preprocessed the collected data, handling missing values, outliers, and normalizing the data.

- Identified the key features that significantly affect crack growth rate, such as stress intensity factor and loading frequency.

- Developed a multi-variate regression equation that relates the selected features to crack growth rate based on the features and data distribution.

- Evaluate the performance of the regression model using the testing data. Utilized metrics like Mean Absolute Error (MAE) and R-squared (R²) to assess model accuracy.

11

Optimisation of pressure vessel for weight reduction

- Implemented four optimization algorithms (Simulated Annealing, Particle Swarm Optimization, Random Search Method, and Genetic Algorithm) using Python.

- Tackled the challenge of multi-variate optimization with eight geometrical design constraints, showcasing a deep understanding of the problem domain.

- Conducted thorough parameter tuning and data normalization, resulting in a comprehensive analysis of the obtained results.

- The Python code significantly optimized computational efficiency and led to a substantial reduction in the weight of a pressure vessel, surpassing existing literature on the subject.

- Awarded the “Best Project” in the class, demonstrating exceptional problem-solving and programming skills.

12

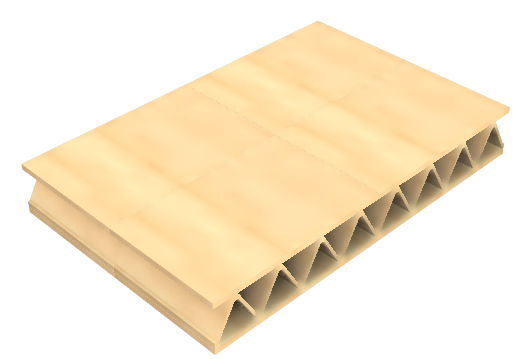

Design and Prototyping of insulation panels

- Designed a biodegradable banana fiber sandwich panel using a corn starch matrix with superior thermal performance than the traditional XPS panel for transport vehicle insulation.

- Conducted extensive research involving thermal and structural simulations in Ansys to optimize the corrugation angle of the panels. This optimization aimed to achieve the dual objectives of reducing weight and maximizing thermal conductivity.

- Successfully prototyped the composite panels using a hand layup process, showcasing the feasibility of the design and manufacturing process.

13

Healthcare Website with Enhanced Doctor Access

- Designed the front-end of a healthcare website aimed at digitizing and efficiently managing patients’ medical history data.

- Utilized HTML and CSS to create an intuitive and user-friendly interface that eliminates the need for paper records.

14

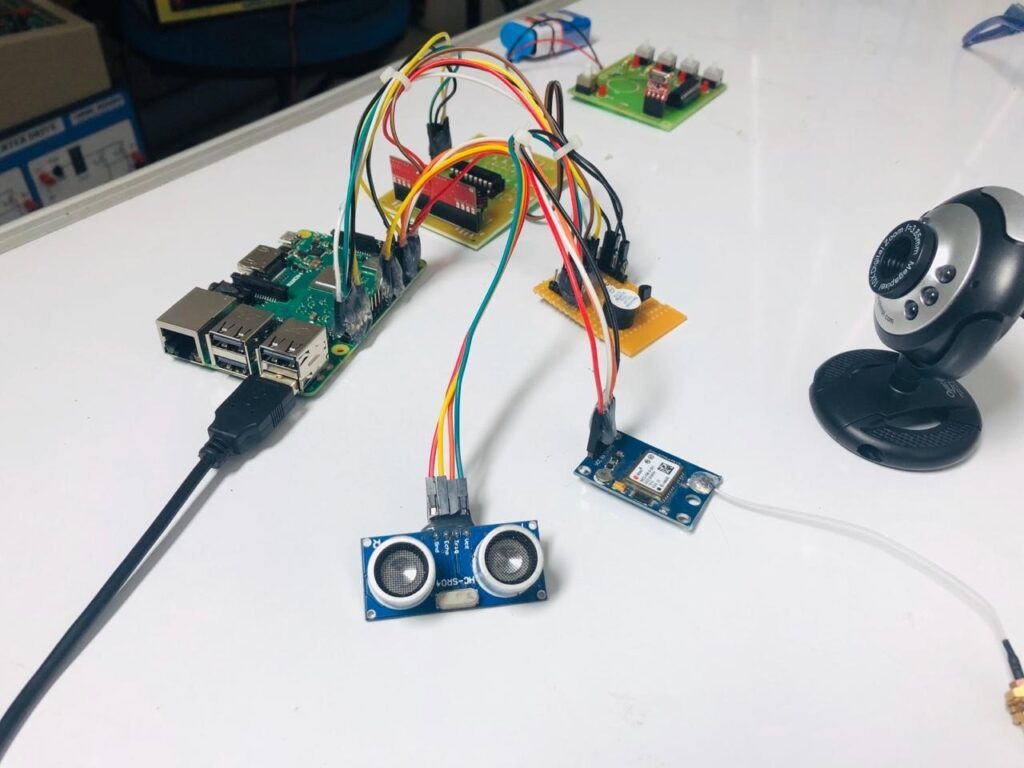

Smart Walking Stick with distance measurement

- Designed a smart walking stick equipped with distance measurement sensors, ensuring obstacle detection and safe navigation.

- Integrated ultrasonic or infrared sensors and a microcontroller to calculate distances and provide real-time feedback to the user.

- Implemented user-friendly features, such as vibration alerts or auditory signals, to warn the user of obstacles or changes in walking conditions.

15

Geneva mechanism design

- Designed a Geneva mechanism tailored for large-scale applications, such as the food packaging industry and industrial automation.

- Utilized Fusion360 to process the CAD model for Additive Manufacturing, which included slicing the model and generating G-code for production.

16

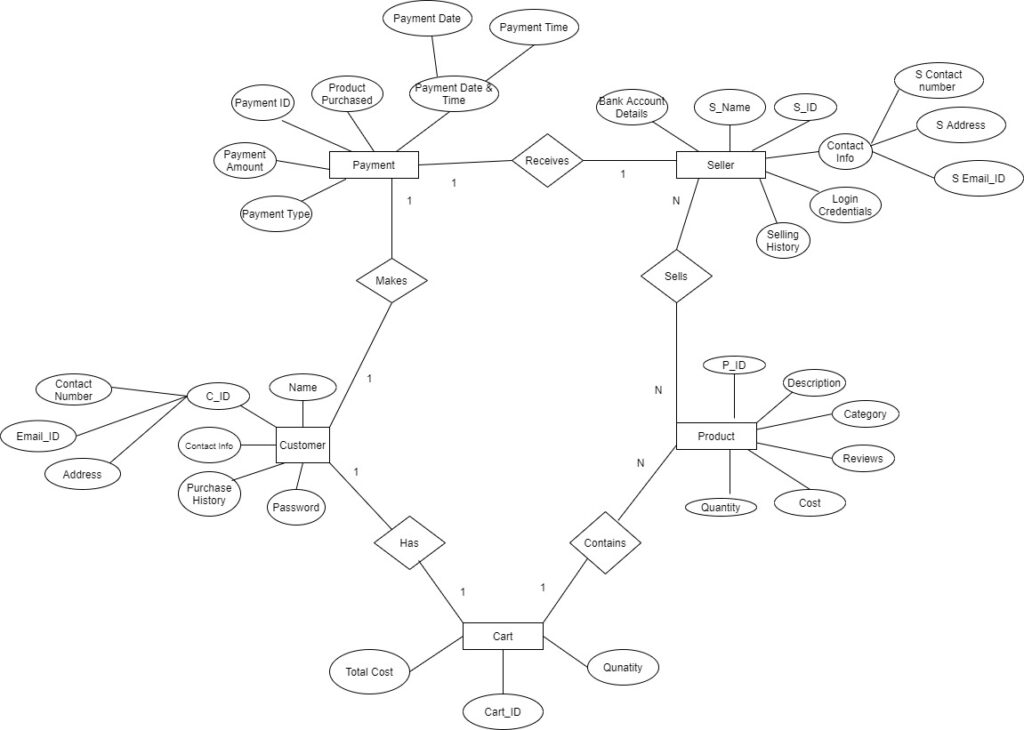

Database management Ecommerce Website to sell electronics

- Designed a smart walking stick equipped with distance measurement sensors, ensuring obstacle detection and safe navigation.

- Integrated ultrasonic or infrared sensors and a microcontroller to calculate distances and provide real-time feedback to the user.

- Implemented user-friendly features, such as vibration alerts or auditory signals, to warn the user of obstacles or changes in walking conditions.

17

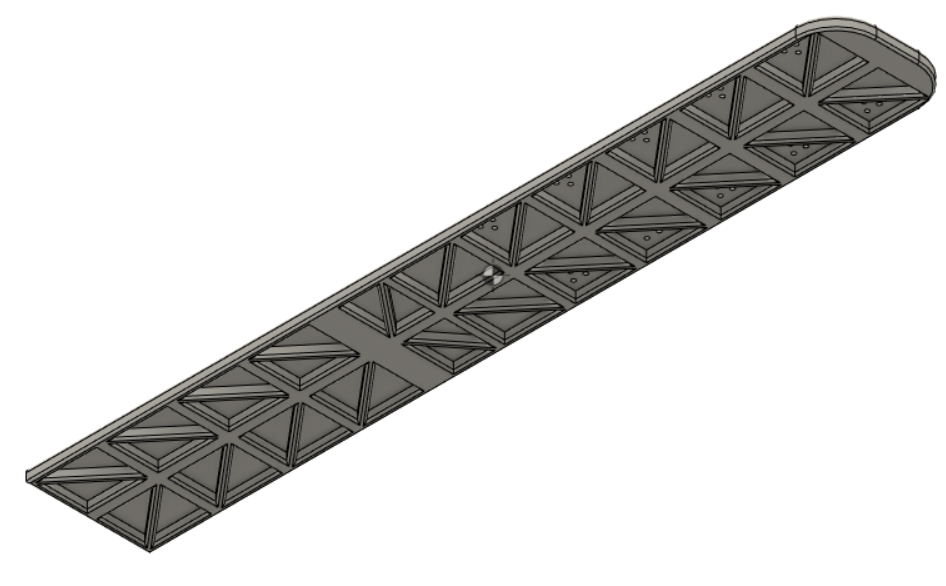

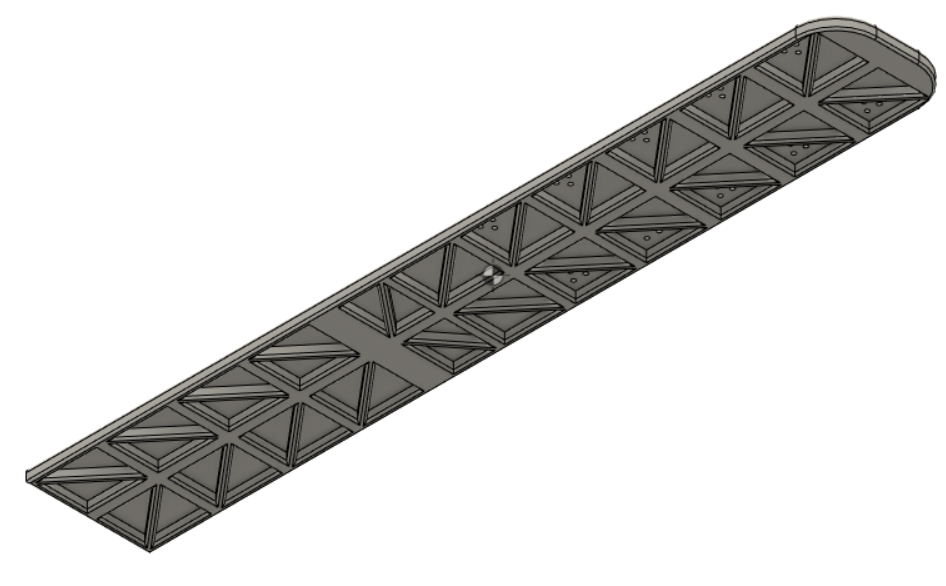

Design of Diving Board

- Designed an overhung diving board with a primary goal of minimizing weight while upholding structural integrity through an iterative design process.

- Employed weight optimization techniques, including strategically incorporating trusses into the board to reduce material without compromising its structural strength.

- Conducted stress analysis using Ansys to ensure the design’s structural integrity, confirming that stress concentrations remained within acceptable limits.